-

Socks steam boarding machine AMS-96/192

This is a new machine with stainless sock seat which have been used to increase the duration of mold used by more than 10 times

-

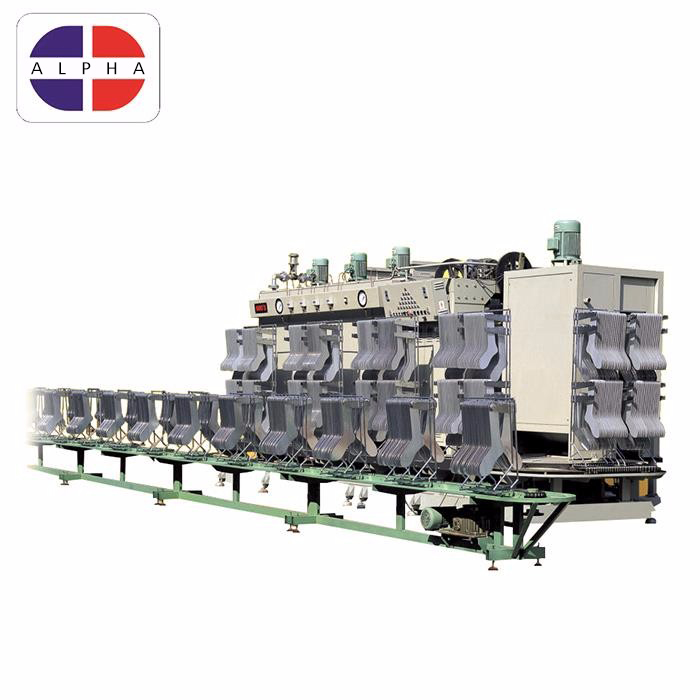

Standard Auto Rotary Steam Setter

This is our popular socks boarding machine model. socks boarding machine can make socks smooth after knitting, this model capacity is high and work steadily with lower energy consumption.

-

Automatic sock steam boarding machine

This is our most automatic device which only 1 person can finish whole process, it is suitable for short socks , semi high socks , long socks . It can save many energy cause its steam chamber is small.

-

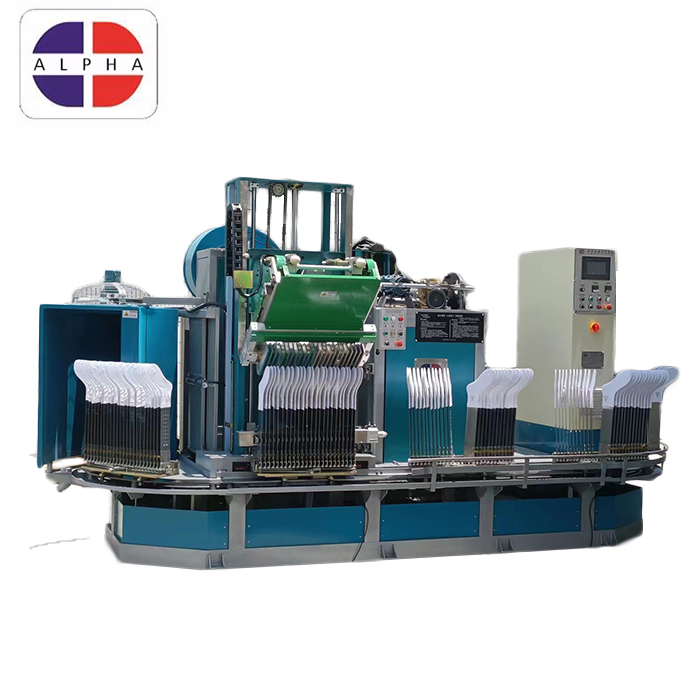

Circular Socks Steam Boarding Machine

Tt sells very well in Japanese and some who has strict require of socks boarding.Circular devices can save a lot of space which 2 workers can run this machine, and socks will get best result after boarding process.

-

Socks steam boarding machine AMS-280P

High capacity socks boarding machine for socks factory.About 4 or 5 workers can operate and easy to handle the whole production.This model we sell most in domestic and foreign market, and customer feedback is very good.

-

Mini socks boarding machine for proofing

Small socks steam boarding machine for high high quality production. 24pcs only needs 1 worker to operate.

-

Double Layer Of Socks steam setter

This model that is special designed by setting for short length socks 100% increased production on existing normal steam setting machine when using two-layer socks board forms comparison with the production,this machine being to 50% reduce the effect on the steam consumption. it consist of two-layer for socks boarding forms,it may reducing as muchi as possible the steam using space in steam chamber in order to it may reduces the consumption steam

-

Mass production socks steam boarding machine

The daily output can reach 100000pairs , and it needs 10 worers to cooperate, very suitable for some large socks baording factory.